Quality inspection, also known as product inspection or product verification, is the process of checking the status and quality of products in all steps of production to ensure that you can get the products you ordered.

Quality inspection will help you ensure that all requirements, specifications and standards you give to the factory have been considered and properly implemented.

Quality inspection is usually carried out in accordance with international quality control standards, such as ANSI/ASQ Z1.4-2003 (equivalent to ISO 2589-1), but we also conduct quality inspections according to your instructions and standards, and based on our professional knowledge and long-term experience .

JMKTS provides comprehensive quality inspection services in Asia, and we can assist you in all stages of production. The following is a list of our quality inspection services:

Before production:

Product inspection gold samples, machines and materials will be used for your order before production and meeting with suppliers and factories (identifying key figures) to ensure that your requirements and specifications are fully understood.

At the beginning of production:

The first batch of products and materials for product inspection will be used for your order. When less than 20% of the products are ready, corrective actions are allowed to be taken as soon as possible.

During production:

At the time of product inspection, 20% to 50% of the products are ready, and when corrective actions are allowed to be implemented, mass production starts, and it is too late.

Focus on checking as many products as possible and cleaning up as many defects as possible.

Continuously supervise the factory, control and recommend the production process and production capacity, and report quality problems and production status daily to help you identify and guide the factory to solve problems in real time.

At the end of production:

Normally, at least 80% or 100% of the products are ready. Product inspection to ensure that the production meets your specifications. It is a must for all buyers.

Focus on checking as many products as possible and cleaning up as many defects as possible.

Container loading supervision will be carried out before the supplier/manufacturer should load the cargo in the container and during the loading process. This kind of inspection is usually carried out in the factory, but can also be carried out in the premises of the freight forwarder.

Which check should I choose?

Ideally, booking product inspections at all stages of production will ensure maximum protection.

In order to save costs, most buyers who buy low to medium quantities will only choose to inspect during the 2 to 3 steps of production, and the most popular inspection is during production and before shipment. Please note that we can help you determine what inspection service you should provide based on your specific situation.

What should I do if the check fails?

You should study the product inspection report in detail and discuss the results and future actions with your factory.

You should also consider our defect classification service, in a specific sample size or full number.

Acceptable Quality Limit (AQL)

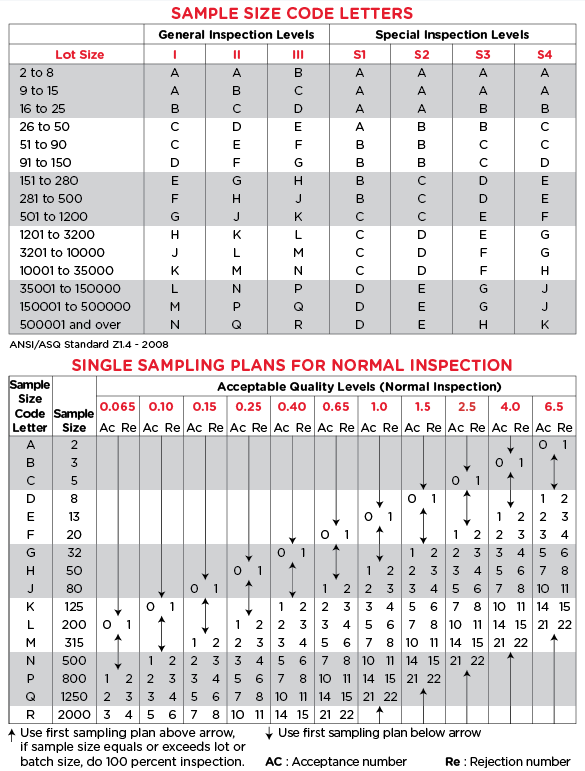

In performing sampling inspection, KTS inspectors exclusively apply the ISO 2859 standard and the tables provided by it. This document, published by the International Organization for Standardization (ISO), is an international standard with equivalents in all national regulations (ANSI/ASQC Z1.4, NF06-022, BS 6001, DIN 40080).

AQL (Acceptable Quality Limit) Sampling is a method widely used to define a production order sample to find whether or not the entire product order has met the client's specifications. Based on the sampling data, the customer can make an informed decision to accept or reject the lot.

Your inspection report will clearly state whether your production has passed or failed your selected Acceptable Quality Tolerance level.

How do I determine the right sample size and acceptance number?

Our trained account managers will be available to ensure you choose the inspection level and AQL values that best suit your needs.

You can already simulate using our sampling calculation tool below: enter your shipment lot quantity, and select sampling levels and AQL to see the impact on inspected quantities and accepted defects.

Example: for a hypothetical inspection of a production with 2,000 units, the client selected level II normal inspection and AQL of 2.5.

In Table A below, the intersection of the respective Lot Size and General Inspection Level indicates sample size code letter K. Then, referring to Table B, we locate row K, which indicates the required sample size of 125. To comply with AQL 2.5, no more than 7 units from that sample size may fail inspection.